VITON / FKM / FPM

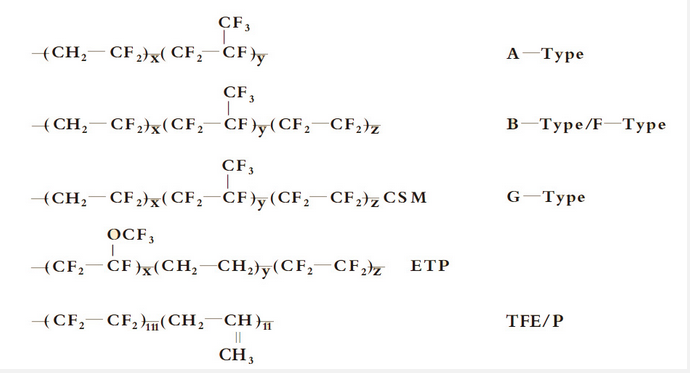

1、Molecular Structure

2、physical and chemical properties

Fluorelastomer refers to the main chain or side chain carbon atoms containing fluorine atoms in the synthesis of high molecular elastomers. Since the CF bond is large (485 kJ per mole) and the covalent radius of the fluorine atom is 0.064 nm, which is half the length of the CC bond, the fluorine atom can shield the CC main chain well and ensure the stability of the CC chain Nature, such as high temperature resistance, oil resistance, chemical resistance, good physical and mechanical properties and weatherability, electrical insulation and radiation resistance, but not resistant to ketones, lipids , Nitro. In all synthetic rubber in its comprehensive performance best, commonly known as "rubber king".

Fluorine rubber is a copolymer of vinyl fluoride and hexafluoropropylene, which entered the market in the mid-1950s, with a specific gravity of 1.85. According to its molecular structure and the amount of fluoride, fluorine rubber chemical resistance and low temperature performance is also different. Fluorine rubber with its in the smoldering (from the fire self-extinguishing), excellent air tightness (vacuum up to 1.33X10-7 ~ 1.33X10-8pa), ozone resistance, weather resistance, good anti-aging and Extensive resistance to performance.

Viton DuPont products made with organic peroxide sulfur have more excellent performance. Viton DuPont grades include: General grade A-type (66% fluorine content), B-type (fluorine content 67-68.5%), F-type GF-type (70% fluorine content), GLT GFLT (low temperature Grade), Viton ETP (better chemical resistance), Viton TFE / P (better acid and alkali resistance).

1) The main advantages:

A, a high degree of chemical stability

Fluorine is one of the best properties of all elastomers in the medium. Resistant oil-based oils, diester oils, silicon ether oils, silicic acid oils, resistant to inorganic acids, resistant to organic, inorganic solvents, pharmaceuticals, etc., are not resistant to low molecular ketones, ethers, esters, intolerance Amine, ammonia, hydrofluoric acid, chlorosulfonic acid, phosphoric acid hydraulic oil.

B, high temperature resistance

Fluorine rubber high temperature performance and silicone rubber, it can be said that the best in the current elastomer. Conventional fluorocarbon limit temperature of 240 ℃, can be used at 220 ℃ for a long time. Special formula of fluoride glue, can be long-term 250 ℃ and 330 ℃ under long-term use.

C, anti-aging

Fluorine rubber has excellent weather resistance, ozone resistance. VitontA, developed by DuPont, is still satisfactory after ten years of natural storage and has no obvious cracking in 45 days of ozone at an ozone concentration of 0.01%.

D, resistance to vacuum performance

Fluorine rubber has excellent resistance to vacuum performance. The vacuum degassing rate of the vulcanizate for the basic formulation of the fluororubber is only 37 x 10-6 Torr / sec. Cm 2.

E, mechanical properties

Fluorine rubber has excellent physical and mechanical properties. Fluorine rubber generally with a strong strength in the 10 ~ 20MPa between the elongation at break between 150 ~ 350%, tear strength between 3 ~ 4KN / m. Some grades of fluorine rubber strength between 15.0 ~ 25MPa, elongation of 200% to 600%, tear strength between 2 ~ 7MPa.

F, electrical performance

Fluorine rubber has good electrical properties and low hygroscopicity than other elastomers, and can be used as a good electrical insulating material for use at low frequency and low pressure.

G, permeability is small

Fluorine rubber on the gas solubility is relatively large, but the diffusion rate is relatively small, so the overall performance of the permeability is also small. Fluorine rubber at 30 ℃ for oxygen, nitrogen, helium, carbon dioxide gas permeability and butyl rubber, butadiene rubber, neoprene, natural rubber is better.

2) Major Disadvantages:

A, low temperature performance is relatively poor

The low temperature performance of the fluororubber is poor due to its own chemical structure. The actual use of fluorine rubber low temperature performance is usually used brittle temperature and compression cold coefficient to represent. The formula of the compound and the shape of the product (such as thickness) have a greater impact on the brittle temperature. If the amount of filler in the formulation increases, the brittle temperature is sensitively deteriorated, the thickness of the product increases, and the brittleness is also susceptible to deterioration

B, radiation resistance is relatively poor

Fluorine rubber radiation resistance is a relatively poor elastomer, fluorine rubber radiation after the performance of cross-linking effect, that is, the cracking effect. Fluorine rubber in the air at room temperature radiation in the 5 × 107 Lun of the dose under the dramatic changes in the conditions of 1 × 107 Lun under the hardness increased by 1 to 3 degrees, the intensity decreased by 20% below the elongation decreased by 30% to 50%.

3、 the temperature range

Static seal: -26 ℃ ~ 232 ℃, a short time up to 275 ℃

Dynamic seal: -15 ℃ ~ 200 ℃

GLT type: -45 ℃ ~ 215 ℃

4、 hardness range

Shore A50 degrees to 90 degrees

5、 color

Brown, black, green, etc., can also be specified by the customer color.

6、 application

Because the fluorine rubber has high temperature resistance, oil, acid and alkali resistance, high vacuum and a variety of chemicals, has been applied in modern aviation, missiles, rockets, space navigation, ship, atomic energy and other cutting-edge technology and automotive, shipbuilding, chemical, petroleum, telecommunications, instrumentation, machinery and other industrial fields.