Dust proof sealing ring

- Introduction

GSLGSZ2GSZ5 JPT1 JPT2

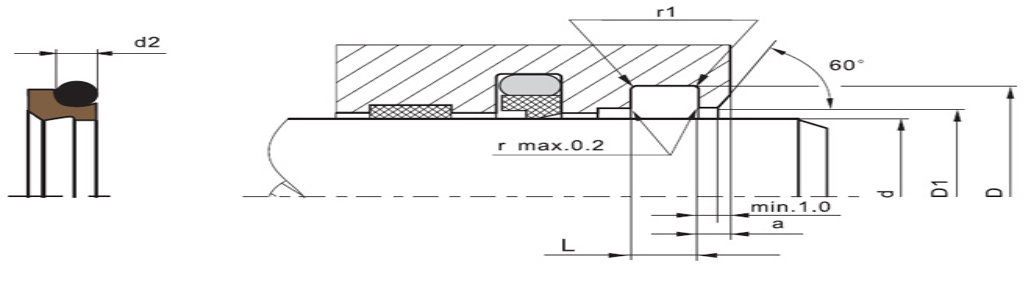

一、Dust proof sealing ring - GSL

1、Product structure characteristics

A single-lip airtight ring consisting of a PTFE wear ring with a dust cap and a rubber O-ring as a preload element.

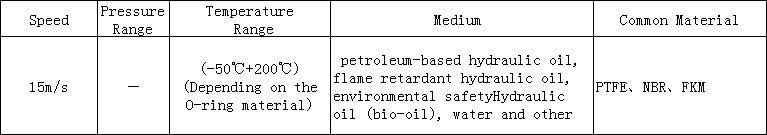

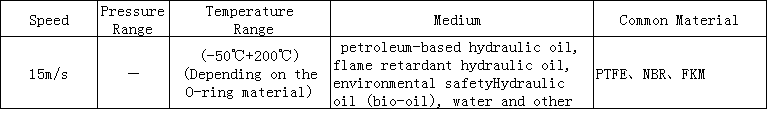

2、Working conditions

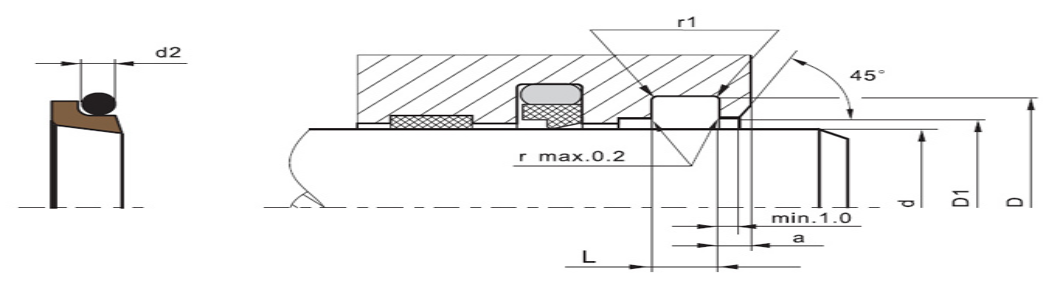

3、Assembly drawings and installation dimensions

| df8 | DH9 | L+0.2 | D1H11 | amin | d2 |

| 40-11.9 | d+4.8 | 3.7 | d+1.5 | 2 | 1.78 |

| 12.0-64.9 | d+6.8 | 5 | d+1.5 | 2 | 2.62 |

| 65.0-250.9 | d+8.8 | 6 | d+1.5 | 3 | 3.53 |

| 251.0-420 | d+12.2 | 8.4 | d+2 | 4 | 5.33 |

| 421.0-650.9 | d+16 | 11 | d+2 | 4 | 7 |

| 651.0-999.9 | d+20 | 14 | d+2.5 | 5 | 8.4 |

| ﹥1000 | d+20 | 14 | d+2.5 | 5 | 8.4 |

4、GSL Specification Table

| S/N | Shaft diameter | Groove diameter | Groove width | S/N | Shaft diameter | Groove diameter | Groove width | |

| df8 | DH9 | L+0.2 | df8 | DH9 | L+0.2 | |||

| GSL0140 | 14 | 20.8 | 5 | GSL1000 | 100 | 108.8 | 6 | |

| GSL0150 | 15 | 21.8 | 5 | GSL1050 | 105 | 113.8 | 6 | |

| GSL0160L | 16 | 20.8 | 3.7 | GSL1100 | 110 | 118.8 | 6 | |

| GSL0160 | 16 | 22.8 | 5 | GSL1150 | 115 | 123.8 | 6 | |

| GSL0180L | 18 | 22.8 | 3.7 | GSL1200 | 120 | 128.8 | 6 | |

| GSL0180 | 18 | 24.8 | 5 | GSL1250 | 125 | 133.8 | 6 | |

| GSL0200 | 20 | 26.8 | 5 | GSL1300 | 130 | 138.8 | 6 | |

| GSL0220 | 22 | 28.8 | 5 | GSL1350 | 135 | 143.8 | 6 | |

| GSL0250 | 25 | 31.8 | 5 | GSL1370 | 137 | 145.8 | 6 | |

| GSL0280 | 28 | 34.8 | 5 | GSL1400 | 140 | 148.8 | 6 | |

| GSL0300L | 30 | 34.8 | 3.7 | GSL1450 | 145 | 153.8 | 6 | |

| GSL0300 | 30 | 36.8 | 5 | GSL1500 | 150 | 158.8 | 6 | |

| GSL0320 | 32 | 38.8 | 5 | GSL1600 | 160 | 168.8 | 6 | |

| GSL0350 | 35 | 41.8 | 5 | GSL1700 | 170 | 178.8 | 6 | |

| GSL0360 | 36 | 42.8 | 5 | GSL1800 | 180 | 188.8 | 6 | |

| GSL0370 | 37 | 43.8 | 5 | GSL1900 | 190 | 198.8 | 6 | |

| GSL0400 | 40 | 46.8 | 5 | GSL2000 | 200 | 208.8 | 6 | |

| GSL0420 | 42 | 48.8 | 5 | GSL2100 | 210 | 218.8 | 6 | |

| GSL0450 | 45 | 51.8 | 5 | GSL2200 | 220 | 228.8 | 6 | |

| GSL0490 | 49 | 55.8 | 5 | GSL2300 | 230 | 238.8 | 6 | |

| GSL0500 | 50 | 56.8 | 5 | GSL2400 | 240 | 248.8 | 6 | |

| GSL0508 | 50.8 | 57.8 | 5 | GSL2500 | 250 | 258.8 | 6 | |

| GSL0540 | 54 | 60.8 | 5 | GSL2600 | 260 | 272.2 | 8.4 | |

| GSL0550 | 55 | 61.8 | 5 | GSL2800 | 280 | 292.2 | 8.4 | |

| GSL0560 | 56 | 62.8 | 5 | GSL3000 | 300 | 321.2 | 8.4 | |

| GSL0600 | 60 | 66.8 | 5 | GSL3200 | 320 | 332.2 | 8.4 | |

| GSL0630 | 63 | 69.8 | 5 | GSL3500 | 350 | 362.2 | 8.4 | |

| GSL0650 | 65 | 73.8 | 6 | GSL3600 | 360 | 372.2 | 8.4 | |

| GSL0700 | 70 | 78.8 | 6 | GSL3700 | 370 | 382.2 | 8.4 | |

| GSL0750 | 75 | 83.8 | 6 | GSL4000 | 400 | 412.2 | 8.4 | |

| GSL0800 | 80 | 88.8 | 6 | GSL4400 | 440 | 456.0 | 11 | |

| GSL0850 | 85 | 93.8 | 6 | GSL4800 | 480 | 496.0 | 11 | |

| GSL0900 | 90 | 98.8 | 6 | GSL5000 | 500 | 516.0 | 11 | |

| GSL0950 | 95 | 103.8 | 6 | GSL5200 | 520 | 536.0 | 11 | |

| GSL5500 | 550 | 566.0 | 11 |

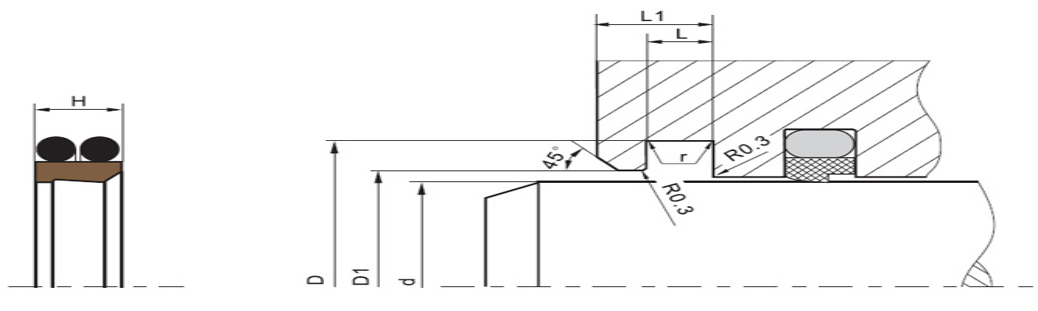

二、Dust proof sealing ring - GSZ2

1、Product structure characteristics

A pair of lip seals made of a PTFE wear ring with a sealing lip and a dust cap and a rubber O-ring as a preload element.

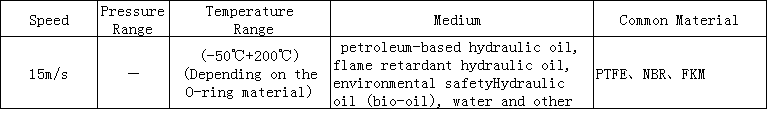

2、Working conditions

3、Assembly drawings and installation dimensions

| df8 | DH9 | L+0.2 | D1H11 | amin | d2 |

| 40-11.9 | d+4.8 | 3.7 | d+1.5 | 2 | 1.78 |

| 12.0-64.9 | d+6.8 | 5.0 | d+1.5 | 2 | 2.62 |

| 65.0-250.9 | d+8.8 | 6.0 | d+1.5 | 3 | 3.53 |

| 251.0-420 | d+12.2 | 8.4 | d+2 | 4 | 5.33 |

| 421.0-650.9 | d+16 | 11.0 | d+2 | 4 | 7.00 |

| 651.0-999.9 | d+20 | 14.0 | d+2.5 | 5 | 8.40 |

| ﹥1000 | d+20 | 14.0 | d+2.5 | 5 | 8.40 |

4、GSZ2 Specification Table

| S/N | Shaft diameter | Groove diameter | Groove width | S/N | Shaft diameter | Groove diameter | Groove width | |

| df8 | DH9 | L+0.2 | df8 | DH9 | L+0.2 | |||

| GSZ2-0140 | 14 | 20.8 | 5 | GSZ2-1000 | 100 | 108.8 | 6 | |

| GSZ2-0150 | 15 | 21.8 | 5 | GSZ2-1050 | 105 | 113.8 | 6 | |

| GSZ2-0160L | 16 | 20.8 | 3.7 | GSZ2-1100 | 110 | 118.8 | 6 | |

| GSZ2-0160 | 16 | 22.8 | 5 | GSZ2-1150 | 115 | 123.8 | 6 | |

| GSZ2-0180L | 18 | 22.8 | 3.7 | GSZ2-1200 | 120 | 128.8 | 6 | |

| GSZ2-0180 | 18 | 24.8 | 5 | GSZ2-1250 | 125 | 133.8 | 6 | |

| GSZ2-0200 | 20 | 26.8 | 5 | GSZ2-1300 | 130 | 138.8 | 6 | |

| GSZ2-0220 | 22 | 28.8 | 5 | GSZ2-1350 | 135 | 143.8 | 6 | |

| GSZ2-0250 | 25 | 31.8 | 5 | GSZ2-1370 | 137 | 145.8 | 6 | |

| GSZ2-0280 | 28 | 34.8 | 5 | GSZ2-1400 | 140 | 148.8 | 6 | |

| GSZ2-0300L | 30 | 34.8 | 3.7 | GSZ2-1450 | 145 | 153.8 | 6 | |

| GSZ2-0300 | 30 | 36.8 | 5 | GSZ2-1500 | 150 | 158.8 | 6 | |

| GSZ2-0320 | 32 | 38.8 | 5 | GSZ2-1600 | 160 | 168.8 | 6 | |

| GSZ2-0350 | 35 | 41.8 | 5 | GSZ2-1700 | 170 | 178.8 | 6 | |

| GSZ2-0360 | 36 | 42.8 | 5 | GSZ2-1800 | 180 | 188.8 | 6 | |

| GSZ2-0370 | 37 | 43.8 | 5 | GSZ2-1900 | 190 | 198.8 | 6 | |

| GSZ2-0400 | 40 | 46.8 | 5 | GSZ2-2000 | 200 | 208.8 | 6 | |

| GSZ2-0420 | 42 | 48.8 | 5 | GSZ2-2100 | 210 | 218.8 | 6 | |

| GSZ2-0450 | 45 | 51.8 | 5 | GSZ2-2200 | 220 | 228.8 | 6 | |

| GSZ2-0490 | 49 | 55.8 | 5 | GSZ2-2300 | 230 | 238.8 | 6 | |

| GSZ2-0500 | 50 | 56.8 | 5 | GSZ2-2400 | 240 | 248.8 | 6 | |

| GSZ2-0508 | 50.8 | 57.8 | 5 | GSZ2-2500 | 250 | 258.8 | 6 | |

| GSZ2-0540 | 54 | 60.8 | 5 | GSZ2-2600 | 260 | 272.2 | 8.4 | |

| GSZ2-0550 | 55 | 61.8 | 5 | GSZ2-2800 | 280 | 292.2 | 8.4 | |

| GSZ2-0560 | 56 | 62.8 | 5 | GSZ2-3000 | 300 | 312.2 | 8.4 | |

| GSZ2-0600 | 60 | 66.8 | 5 | GSZ2-3200 | 320 | 332.2 | 8.4 | |

| GSZ2-0630 | 63 | 69.8 | 5 | GSZ2-3500 | 350 | 362.2 | 8.4 | |

| GSZ2-0650 | 65 | 73.8 | 6 | GSZ2-3600 | 360 | 372.2 | 8.4 | |

| GSZ2-0700 | 70 | 78.8 | 6 | GSZ2-3700 | 370 | 382.2 | 8.4 | |

| GSZ2-0750 | 75 | 83.8 | 6 | GSZ2-4000 | 400 | 412.2 | 8.4 | |

| GSZ2-0800 | 80 | 88.8 | 6 | GSZ2-4400 | 440 | 456.0 | 11 | |

| GSZ2-0850 | 85 | 93.8 | 6 | GSZ2-4800 | 480 | 496.0 | 11 | |

| GSZ2-0900 | 90 | 98.8 | 6 | GSZ2-5000 | 500 | 516.0 | 11 | |

| GSZ2-0950 | 95 | 103.8 | 6 | GSZ2-5200 | 520 | 536.0 | 11 | |

| GSZ2-5500 | 550 | 566.0 | 11 | |||||

三、Dust proof sealing ring - GSZ5

1、Product structure characteristics

A pair of lip seals made of a PTFE wear ring with a sealing lip and a dust cap and a rubber O-ring as a preload element.

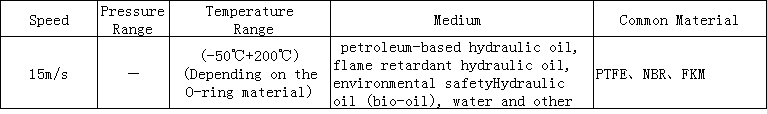

2、Working conditions

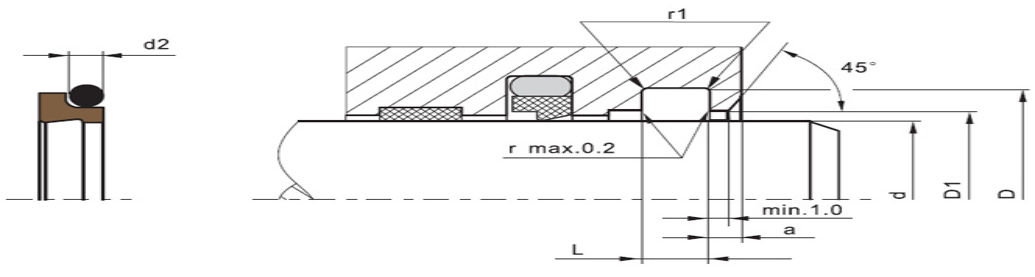

3、Assembly drawings and installation dimensions

| df8 | DH9 | L+0.2 | D1H11 | amin | d2 |

| 19.0-39.9 | d+7.6 | 4.2 | d+1.5 | 3 | 2.62 |

| 40.0-69.9 | d+8.8 | 6.3 | d+1.5 | 2 | 2.62 |

| 70.0-139.9 | d+12.2 | 8.1 | d+2.0 | 4 | 3.53 |

| 140.0-399.9 | d+16.0 | 9.5 | d+2.5 | 5 | 5.33 |

| 400.0-649.9 | d+24.0 | 14.0 | d+2.5 | 8 | 7.00 |

| 650.0-999.9 | d+27.3 | 16.0 | d+2.5 | 10 | 8.40 |

| ﹥1000 | d+27.3 | 16.0 | d+2.5 | 10 | 8.40 |

4、GSZ2 Specification Table

| S/N | Shaft diameter | Groove diameter | Groove width | S/N | Shaft diameter | Groove diameter | Groove width | |

| df8 | DH9 | L+0.2 | df8 | DH9 | L+0.2 | |||

| GSZ5-0200 | 20 | 27.6 | 4.2 | GSZ5-1500 | 150 | 166 | 9.5 | |

| GSZ5-0250 | 25 | 32.6 | 4.2 | GSZ5-1530 | 153 | 169 | 9.5 | |

| GSZ5-0280 | 28 | 35.6 | 4.2 | GSZ5-1550 | 155 | 171 | 9.5 | |

| GSZ5-0300 | 30 | 37.6 | 4.2 | GSZ5-1600 | 160 | 172.2 | 8.1 | |

| GSZ5-0320 | 32 | 39.6 | 4.2 | GSZ5-1600/1 | 160 | 176 | 9.5 | |

| GSZ5-0360 | 36 | 43.6 | 4.2 | GSZ5-1650 | 165 | 181 | 9.5 | |

| GSZ5-0400 | 40 | 48.6 | 6.3 | GSZ5-1700 | 170 | 186 | 9.5 | |

| GSZ5-0420 | 42 | 50.8 | 6.3 | GSZ5-1750 | 175 | 191 | 9.5 | |

| GSZ5-0450 | 45 | 53.8 | 6.3 | GSZ5-1800 | 180 | 192.2 | 8.1 | |

| GSZ5-0500 | 50 | 58.8 | 6.3 | GSZ5-1800/1 | 180 | 196 | 9.5 | |

| GSZ5-0550 | 55 | 63.8 | 6.3 | GSZ5-1882 | 188.2 | 204.2 | 9.5 | |

| GSZ5-0560 | 56 | 64.8 | 6.3 | GSZ5-1900 | 190 | 206 | 9.5 | |

| GSZ5-0600 | 60 | 68.8 | 6.3 | GSZ5-1920 | 192 | 208 | 9.5 | |

| GSZ5-0630 | 63 | 71.8 | 6.3 | GSZ5-2000 | 200 | 212.2 | 8.1 | |

| GSZ5-0650 | 65 | 73.8 | 6.3 | GSZ5-2000/1 | 200 | 216 | 9.5 | |

| GSZ5-0700 | 70 | 78.8 | 6.3 | GSZ5-2110 | 211 | 227 | 9.5 | |

| GSZ5-0700/1 | 70 | 82.2 | 8.1 | GSZ5-2200 | 220 | 232.2 | 8.1 | |

| GSZ5-0750 | 75 | 87.2 | 8.1 | GSZ5-2200/1 | 220 | 236 | 9.5 | |

| GSZ5-0800 | 80 | 88.8 | 6.3 | GSZ5-2400 | 240 | 256 | 9.5 | |

| GSZ5-0800/1 | 80 | 92.2 | 8.1 | GSZ5-2500 | 250 | 262.2 | 8.1 | |

| GSZ5-0850 | 85 | 97.2 | 8.1 | GSZ5-2500/1 | 250 | 266 | 9.5 | |

| GSZ5-0900 | 90 | 98.8 | 6.3 | GSZ5-2600 | 260 | 276 | 9.5 | |

| GSZ5-0900/1 | 90 | 102.2 | 8.1 | GSZ5-2700 | 270 | 286 | 9.5 | |

| GSZ5-0970 | 97 | 109.2 | 8.1 | GSZ5-2800 | 280 | 292.2 | 8.1 | |

| GSZ5-0990 | 99 | 111.2 | 8.1 | GSZ5-2800/1 | 280 | 296 | 9.5 | |

| GSZ5-1000 | 100 | 108.8 | 6.3 | GSZ5-3000 | 300 | 316 | 9.5 | |

| GSZ5-1000/1 | 100 | 112.2 | 8.1 | GSZ5-3200 | 320 | 332 | 8.1 | |

| GSZ5-1050 | 105 | 117.2 | 8.1 | GSZ5-3200/1 | 320 | 336 | 9.5 | |

| GSZ5-1100 | 110 | 118.2 | 6.3 | GSZ5-3300 | 330 | 346 | 9.5 | |

| GSZ5-1100/1 | 110 | 122.2 | 8.1 | GSZ5-3500 | 350 | 366 | 9.5 | |

| GSZ5-1150 | 115 | 127.2 | 8.1 | GSZ5-3600 | 360 | 372.2 | 8.1 | |

| GSZ5-1200 | 120 | 132.2 | 8.1 | GSZ5-3600/1 | 360 | 376 | 9.5 | |

| GSZ5-1250/1 | 125 | 133.8 | 6.3 | GSZ5-3800 | 380 | 396 | 9.5 | |

| GSZ5-1250/2 | 125 | 137.2 | 8.1 | GSZ5-4000 | 400 | 424 | 14.0 | |

| GSZ5-1250 | 125.4 | 137.6 | 8.1 | GSZ5-4400 | 440 | 464 | 14.0 | |

| GSZ5-1300 | 130 | 142.2 | 8.1 | GSZ5-4500 | 450 | 474 | 14.0 | |

| GSZ5-1400 | 135 | 147.2 | 8.1 | GSZ5-4800 | 480 | 504 | 14.0 | |

| GSZ5-1400/1 | 140 | 152.2 | 8.1 | GSZ5-5000 | 500 | 524 | 14.0 | |

| GSZ5-1400/2 | 140 | 156.0 | 9.5 | GSZ5-5500 | 550 | 574 | 14.0 | |

| GSZ5-1405 | 140.5 | 156.5 | 9.5 |

四、Dust proof sealing ring - JPT1

1、Product structure characteristics

A pair of lip seals made of a PTFE wear ring with a sealing lip and a dust cap and two rubber O-rings as a preload element.

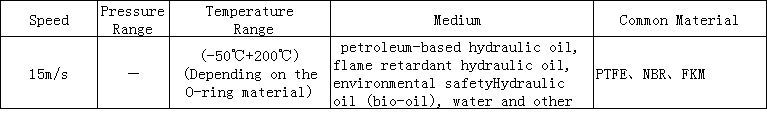

2、Working conditions

3、Assembly drawings and installation dimensions

| df8 | DH9 | L+0.2 | D1+/-0.1 | L1 | r |

| 20-39.9 | d+7.6 | 4.2 | d+1.0 | 8.2 | 0.4 |

| 40-69.9 | d+8.8 | 6.3 | d+1.5 | 10.3 | 1.2 |

| 70-139.9 | d+12.2 | 8.1 | d+2.0 | 12.1 | 2.0 |

| 140-399.9 | d+16.0 | 11.5 | d+2.0 | 15.5 | 2.0 |

| 400-649.9 | d+24.0 | 15.5 | d+2.5 | 19.5 | 2.0 |

| 650-999.9 | d+27.3 | 18 | d+2.5 | 23.0 | 2.0 |

4、GSZ2 Specification Table

| S/N | df8 | DH9 | H | L+0.2 | S/N | d f8 | DH9 | H | L+0.2 | |

| JPT1-0200 | 20 | 27.6 | 4 | 4.2 | JPT1-2200 | 220 | 236 | 11 | 11.5 | |

| JPT1-0250 | 25 | 32.6 | 4 | 4.2 | JPT1-2300 | 230 | 246 | 11 | 11.5 | |

| JPT1-0280 | 28 | 35.6 | 4 | 4.2 | JPT1-2400 | 240 | 256 | 11 | 11.5 | |

| JPT1-0300 | 30 | 37.6 | 4 | 4.2 | JPT1-2450 | 245 | 261 | 11 | 11.5 | |

| JPT1-0320 | 32 | 39.6 | 4 | 4.2 | JPT1-2500 | 250 | 266 | 11 | 11.5 | |

| JPT1-0350 | 35 | 42.6 | 4 | 4.2 | JPT1-2600 | 260 | 276 | 11 | 11.5 | |

| JPT1-0360 | 36 | 43.6 | 4 | 4.2 | JPT1-2800 | 280 | 296 | 11 | 11.5 | |

| JPT1-0400 | 40 | 48.8 | 6 | 6.3 | JPT1-2900 | 290 | 306 | 11 | 11.5 | |

| JPT1-0420 | 42 | 50.8 | 6 | 6.3 | JPT1-3000 | 300 | 316 | 11 | 11.5 | |

| JPT1-0450 | 45 | 53.8 | 6 | 6.3 | JPT1-3200 | 320 | 336 | 11 | 11.5 | |

| JPT1-0500 | 50 | 58.8 | 6 | 6.3 | JPT1-3400 | 340 | 356 | 11 | 11.5 | |

| JPT1-0550 | 55 | 63.8 | 6 | 6.3 | JPT1-3550 | 355 | 371 | 11 | 11.5 | |

| JPT1-0560 | 56 | 64.8 | 6 | 6.3 | JPT1-3600 | 360 | 376 | 11 | 11.5 | |

| JPT1-0600 | 60 | 68.8 | 6 | 6.3 | JPT1-3700 | 370 | 386 | 11 | 11.5 | |

| JPT1-0630 | 63 | 71.8 | 6 | 6.3 | JPT1-3750 | 375 | 391 | 11 | 11.5 | |

| JPT1-0650 | 65 | 73.8 | 6 | 6.3 | JPT1-3800 | 380 | 396 | 11 | 11.5 | |

| JPT1-0700 | 70 | 82.2 | 7.7 | 8.1 | JPT1-3900 | 390 | 406 | 11 | 11.5 | |

| JPT1-0750 | 75 | 87.2 | 7.7 | 8.1 | JPT1-4000 | 400 | 424 | 14.8 | 15.5 | |

| JPT1-0800 | 80 | 92.2 | 7.7 | 8.1 | JPT1-4100 | 410 | 434 | 14.8 | 15.5 | |

| JPT1-0850 | 85 | 97.2 | 7.7 | 8.1 | JPT1-4200 | 420 | 444 | 14.8 | 15.5 | |

| JPT1-0900 | 90 | 102.2 | 7.7 | 8.1 | JPT1-4300 | 420 | 454 | 14.8 | 15.5 | |

| JPT1-1000 | 100 | 112.2 | 7.7 | 8.1 | JPT1-4400 | 430 | 464 | 14.8 | 15.5 | |

| JPT1-1100 | 110 | 122.2 | 7.7 | 8.1 | JPT1-4500 | 440 | 474 | 14.8 | 15.5 | |

| JPT1-1150 | 115 | 127.2 | 7.7 | 8.1 | JPT1-4600 | 460 | 484 | 14.8 | 15.5 | |

| JPT1-1200 | 120 | 132.2 | 7.7 | 8.1 | JPT1-4700 | 470 | 494 | 14.8 | 15.5 | |

| JPT1-1250 | 125 | 137.2 | 7.7 | 8.1 | JPT1-4800 | 480 | 504 | 14.8 | 15.5 | |

| JPT1-1300 | 130 | 142.2 | 7.7 | 8.1 | JPT1-5000 | 500 | 524 | 14.8 | 15.5 | |

| JPT1-1400 | 140 | 156.0 | 11 | 11.5 | JPT1-5100 | 510 | 534 | 14.8 | 15.5 | |

| JPT1-1500 | 150 | 166.0 | 11 | 11.5 | JPT1-5200 | 520 | 544 | 14.8 | 15.5 | |

| JPT1-1600 | 160 | 176.0 | 11 | 11.5 | JPT1-5300 | 530 | 554 | 14.8 | 15.5 | |

| JPT1-1700 | 170 | 186.0 | 11 | 11.5 | JPT1-5400 | 540 | 564 | 14.8 | 15.5 | |

| JPT1-1800 | 180 | 196.0 | 11 | 11.5 | JPT1-5500 | 550 | 574 | 14.8 | 15.5 | |

| JPT1-2000 | 200 | 216.0 | 11 | 11.5 |

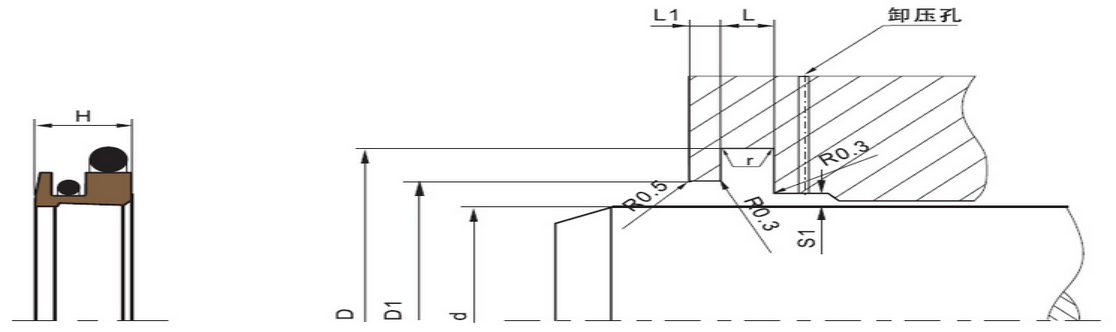

五、Dust proof sealing ring - JPT1

1、Product structure characteristics

A pair of lip seals made of a PTFE wear ring with a sealing lip and a dust cap and two rubber O-rings as a preload element.

2、Working conditions

3、Assembly drawings and installation dimensions

| df8 | DH9 | L+0.2 | D1+/-0.1 | r | L1 |

| 100-450 | d+22.2 | 6.3 | d+10.7 | 1.2 | 4.2 |

| 220-450 | d+24.2 | 6.3 | d+10.7 | 1.2 | 4.2 |

| 250-650 | d+33.0 | 8.1 | d+15.1 | 1.2 | 6.3 |

| 500 | d+36.5 | 9.5 | d+15.1 | 2.0 | 6.3 |

4、GSZ2 Specification Table

| S/N | df8 | DH9 | H | L+0.2 | L1 | S/N | df8 | DH9 | H | L+0.2 | L1 | |

| JPT2-1000 | 100 | 122.2 | 13.5 | 6.3 | 4.2 | JPT2-2950 | 295.0 | 319.2 | 13.5 | 6.3 | 4.2 | |

| JPT2-1100 | 110 | 132.2 | 13.5 | 6.3 | 4.2 | JPT2-3000 | 300.0 | 333.0 | 18.4 | 8.1 | 6.3 | |

| JPT2-1200 | 120 | 142.2 | 13.5 | 6.3 | 4.2 | JPT2-3302 | 330.2 | 363.2 | 18.4 | 8.1 | 6.3 | |

| JPT2-1300 | 130 | 152.2 | 13.5 | 6.3 | 4.2 | JPT2-3500 | 350.0 | 383.0 | 18.4 | 8.1 | 6.3 | |

| JPT2-1397 | 139.7 | 161.9 | 13.5 | 6.3 | 4.2 | JPT2-3600 | 360.0 | 393.0 | 18.4 | 8.1 | 6.3 | |

| JPT2-1400 | 140 | 162.2 | 13.5 | 6.3 | 4.2 | JPT2-3700 | 370.0 | 403.0 | 18.4 | 8.1 | 6.3 | |

| JPT2-1500 | 150 | 172.2 | 13.5 | 6.3 | 4.2 | JPT2-3800 | 380.0 | 413.0 | 18.4 | 8.1 | 6.3 | |

| JPT2-1600 | 160 | 182.2 | 13.5 | 6.3 | 4.2 | JPT2-3850 | 385.0 | 418.0 | 18.4 | 8.1 | 6.3 | |

| JPT2-1700 | 170 | 192.2 | 13.5 | 6.3 | 4.2 | JPT2-3900 | 390.0 | 423.0 | 18.4 | 8.1 | 6.3 | |

| JPT2-1800 | 180 | 202.2 | 13.5 | 6.3 | 4.2 | JPT2-4000 | 400.0 | 433.0 | 18.4 | 8.1 | 6.3 | |

| JPT2-2000 | 200 | 222.2 | 13.5 | 6.3 | 4.2 | JPT2-4200 | 420.0 | 453.0 | 18.4 | 8.1 | 6.3 | |

| JPT2-2100 | 210 | 232.2 | 13.5 | 6.3 | 4.2 | JPT2-4300 | 430.0 | 463.0 | 18.4 | 8.1 | 6.3 | |

| JPT2-2200 | 220 | 242.2 | 13.5 | 6.3 | 4.2 | JPT2-4318 | 431.8 | 464.8 | 18.4 | 8.1 | 6.3 | |

| JPT2-2286 | 228.6 | 250.2 | 13.5 | 6.3 | 4.2 | JPT2-4500 | 450.0 | 483.0 | 18.4 | 8.1 | 6.3 | |

| JPT2-2300 | 230 | 254.2 | 13.5 | 6.3 | 4.2 | JPT2-4700 | 470.0 | 503.0 | 18.4 | 8.1 | 6.3 | |

| JPT2-2400 | 240 | 264.2 | 13.5 | 6.3 | 4.2 | JPT2-4800 | 480.0 | 513.0 | 18.4 | 8.1 | 6.3 | |

| JPT2-2600 | 260 | 284.2 | 13.5 | 6.3 | 4.2 | JPT2-5000 | 500.0 | 533.0 | 18.4 | 8.1 | 6.3 | |

| JPT2-2750 | 275 | 299.2 | 13.5 | 6.3 | 4.2 | JPT2-5100 | 510.0 | 543.0 | 18.4 | 8.1 | 6.3 | |

| JPT2-2800 | 280 | 304.2 | 13.5 | 6.3 | 4.2 | JPT2-5600 | 560.0 | 593.0 | 18.4 | 8.1 | 6.3 |