Glyd Ring for Rod

- Introduction

一、Glyd Ring for Rod - GSI

1、Product structure characteristics

It consists of a PTFE seal and a rubber O-ring as a preload element.

It is a reciprocating seal that can withstand bidirectional effects of high pressure, low pressure and heavy load and alternating pressure.

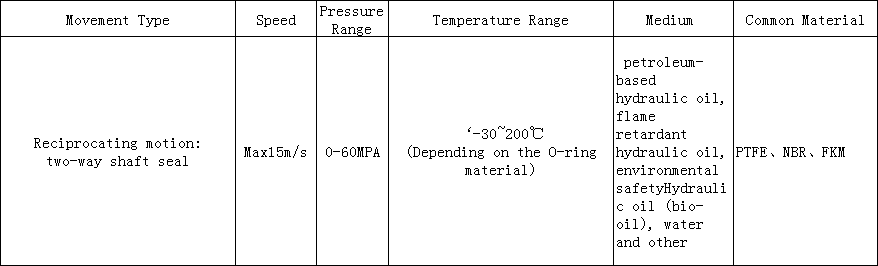

2、Working conditions

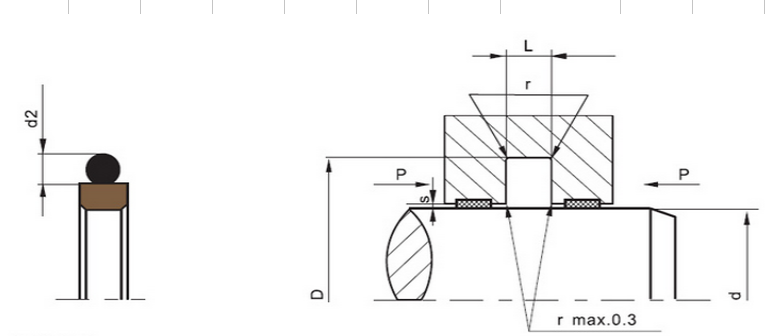

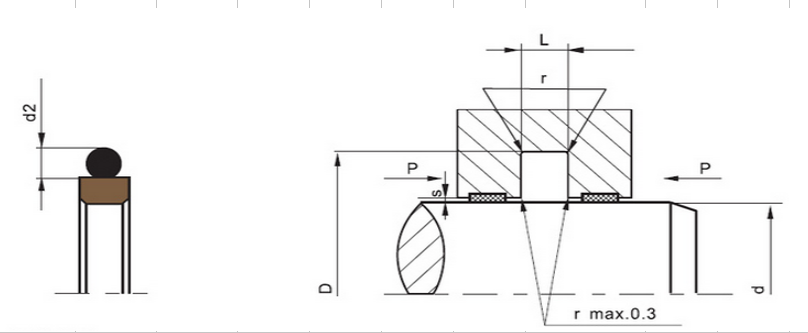

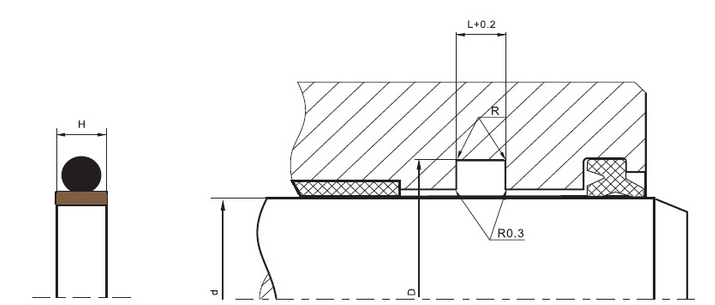

3、Assembly drawings and installation dimensions

| Shaft diameter dh9 | Groove diameter | Groove width | Fillet | Radial clearance Smax | O-ring section | ||||

| Standard Specification | Light | Heavy | DH9 | L+0.2 | r | 10Mpa | 20Mpa | 40Mpa | d2 |

| 3-7.9 | 8-18.9 | - | d+4.9 | 2.2 | 0.4 | 0.4 | 0.2 | 0.15 | 1.78 |

| 8-18.9 | 19-37.9 | - | d+7.3 | 3.2 | 0.6 | 0.6 | 0.25 | 0.15 | 2.62 |

| 19-37.9 | 38-199.9 | 8-18.9 | d+10.7 | 4.2 | 1.0 | 1.0 | 0.25 | 0.20 | 3.53 |

| 38-199.9 | 200-255.9 | 19-37.9 | d+15.1 | 6.3 | 1.3 | 1.3 | 0.30 | 0.20 | 5.33 |

| 200-255.9 | 256-649.9 | 38-199.9 | d+20.5 | 8.1 | 1.8 | 1.8 | 0.35 | 0.25 | 7.00 |

| 256-649.9 | 650-999.9 | 200-255.9 | d+24.0 | 8.1 | 1.8 | 1.8 | 0.35 | 0.25 | 7.00 |

| 650-999.9 | >=1000 | 256-649.9 | d+27.3 | 9.5 | 2.5 | 2.5 | 0.50 | 0.30 | 8.40 |

| >=1000 | - | 650-999.9 | d+38.0 | 13.8 | 3.0 | 3.0 | 0.70 | 0.60 | 12.00 |

4、GSI Specification Table

| S/N | Shaft diameter | Groove diameter | Groove width | S/N | Shaft diameter | Groove diameter | Groove width | |

| dh9 | DH9 | L+0.2 | dh9 | DH9 | L+0.2 | |||

| GSI0080 | 8 | 15.3 | 3.2 | GSI1120 | 112 | 127.1 | 6.3 | |

| GSI0100 | 10 | 17.3 | 3.2 | GSI1150 | 115 | 130.1 | 6.3 | |

| GSI0120 | 12 | 19.3 | 3.2 | GSI1180 | 118 | 133.1 | 6.3 | |

| GSI0140 | 14 | 21.3 | 3.2 | GSI1200 | 120 | 135.1 | 6.3 | |

| GSI0150 | 15 | 22.3 | 3.2 | GSI1250 | 125 | 140.1 | 6.3 | |

| GSI0180 | 18 | 25.3 | 3.2 | GSI1300 | 130 | 145.1 | 6.3 | |

| GSI0190 | 19 | 29.7 | 4.2 | GSI1350 | 135 | 150.1 | 6.3 | |

| GSI0200 | 20 | 30.7 | 4.2 | GSI1400L | 140 | 150.7 | 4.2 | |

| GSI0220 | 22 | 32.7 | 4.2 | GSI1400 | 140 | 155.1 | 6.3 | |

| GSI0250 | 25 | 35.7 | 4.2 | GSI1450 | 145 | 160.1 | 6.3 | |

| GSI0254 | 25.4 | 36.1 | 4.2 | GSI1500 | 150 | 165.1 | 6.3 | |

| GSI0260 | 26 | 36.7 | 4.2 | GSI1600 | 160 | 175.1 | 6.3 | |

| GSI0280 | 28 | 38.7 | 4.2 | GSI1600H | 160 | 180.5 | 8.1 | |

| GSI0300 | 30 | 40.7 | 4.2 | GSI1650 | 165 | 180.1 | 6.3 | |

| GSI0320 | 32 | 42.7 | 4.2 | GSI1700L | 170 | 180.7 | 4.2 | |

| GSI0350 | 35 | 45.7 | 4.2 | GSI1700 | 170 | 185.1 | 6.3 | |

| GSI0360 | 36 | 46.7 | 4.2 | GSI1750 | 175 | 190.1 | 6.3 | |

| GSI0380 | 38 | 53.1 | 6.3 | GSI1800 | 180 | 195.1 | 6.3 | |

| GSI0400 | 40 | 55.1 | 6.3 | GSI1800H | 180 | 200.5 | 8.1 | |

| GSI0420 | 42 | 57.1 | 6.3 | GSI1900 | 190 | 205.1 | 6.3 | |

| GSI0450 | 45 | 60.1 | 6.3 | GSI2000L | 200 | 215.1 | 6.3 | |

| GSI0480 | 48 | 63.1 | 6.3 | GSI2000 | 200 | 220.5 | 8.1 | |

| GSI0500 | 50 | 65.1 | 6.3 | GSI2100 | 210 | 230.5 | 8.1 | |

| GSI0508 | 50.8 | 65.9 | 6.3 | GSI2200L | 220 | 235.1 | 6.3 | |

| GSI0550 | 55 | 70.1 | 6.3 | GSI2200 | 220 | 240.5 | 8.1 | |

| GSI0600 | 60 | 75.1 | 6.3 | GSI2300L | 230 | 245.1 | 6.3 | |

| GSI0630 | 63 | 78.1 | 6.3 | GSI2300 | 230 | 250.5 | 8.1 | |

| GSI0650 | 65 | 80.1 | 6.3 | GSI2400 | 240 | 260.5 | 8.1 | |

| GSI0700 | 70 | 85.1 | 6.3 | GSI2500 | 250 | 270.5 | 8.1 | |

| GSI0750 | 75 | 90.1 | 6.3 | GSI2600 | 260 | 284.0 | 8.1 | |

| GSI0800L | 80 | 90.7 | 6.3 | GSI2700L | 270 | 290.5 | 8.1 | |

| GSI0800 | 80 | 95.1 | 6.3 | GSI2700 | 270 | 294.0 | 8.1 | |

| GSI0850 | 85 | 100.1 | 6.3 | GSI2750 | 275 | 299.0 | 8.1 | |

| GSI0900 | 90 | 105.1 | 6.3 | GSI2800L | 280 | 300.5 | 8.1 | |

| GSI0950 | 95 | 110.1 | 6.3 | GSI2800 | 280 | 304.0 | 8.1 | |

| GSI1000 | 100 | 110.7 | 6.3 | GSI2900 | 290 | 314.0 | 8.1 | |

| GSI1000L | 100 | 115.1 | 6.3 | GSI3000 | 300 | 324.0 | 8.1 | |

| GSI1016 | 101.6 | 116.7 | 6.3 | GSI3100 | 310 | 334.0 | 8.1 | |

| GSI11050 | 105 | 120.1 | 6.3 | GSI3200 | 320 | 344.0 | 8.1 | |

| GSI1100 | 110 | 125.1 | 6.3 | GSI3300 | 330 | 354.0 | 8.1 | |

| GSI1100H | 110 | 130.5 | 8.1 | GSI3400 | 340 | 364.0 | 8.1 |

二、Glyd Ring for Rod - GSR

1、Product structure characteristics

It consists of a PTFE seal and a rubber O-ring as a preload element.

It is a reciprocating seal that can withstand bidirectional effects of high pressure, low pressure and heavy load and alternating pressure.

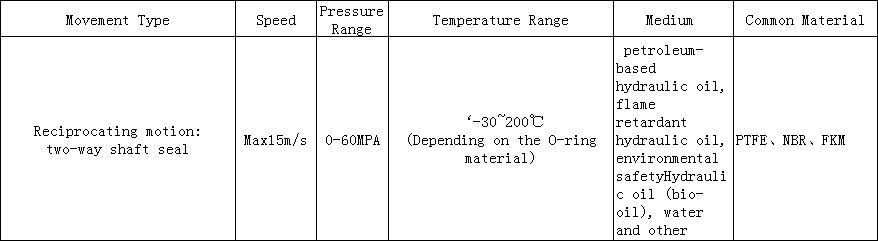

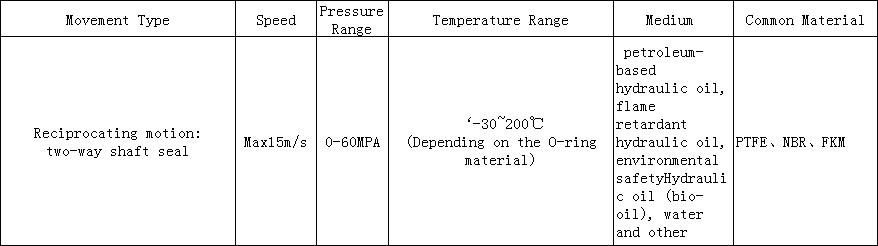

2、Working conditions

3、Assembly drawings and installation dimensions

| Shaft diameter | Groove diameter | Groove width | Fillet | Radial clearance Smax | O-ring section | ||

| dh9 | DH9 | L+0.2 | r | 10Mpa | 20Mpa | 40Mpa | d2 |

| 10-29.9 | d+8 | 3.2 | 0.6 | 0.6 | 0.25 | 0.15 | 2.62 |

| 30-79.9 | d+10 | 4.2 | 1 | 1.0 | 0.25 | 0.20 | 3.53 |

| 80-179.9 | d+15 | 6.8 | 1.3 | 1.3 | 0.30 | 0.20 | 5.33 |

| 180-284.9 | d+20 | 8.1 | 1.8 | 1.8 | 0.35 | 0.25 | 7.00 |

| 285-600 | d+25 | 9.5 | 2.5 | 2.5 | 0.50 | 0.30 | 8.40 |

4、GSR Specification Table

| S/N | Shaft diameter | Groove diameter | Groove width | S/N | Shaft diameter | Groove diameter | Groove width | |

| dh9 | DH9 | L+0.2 | dh9 | DH9 | L+0.2 | |||

| GSR0100 | 10 | 18 | 3.2 | GSR1300 | 130 | 145 | 6.8 | |

| GSR0120 | 12 | 20 | 3.2 | GSR1350 | 135 | 150 | 6.8 | |

| GSR0140 | 14 | 22 | 3.2 | GSR1400 | 140 | 155 | 6.8 | |

| GSR0160 | 16 | 24 | 3.2 | GSR1450 | 145 | 160 | 6.8 | |

| GSR0180 | 18 | 26 | 3.2 | GSR1500 | 150 | 165 | 6.8 | |

| GSR0200 | 20 | 28 | 3.2 | GSR1550 | 155 | 170 | 6.8 | |

| GSR0250 | 25 | 33 | 3.2 | GSR1600 | 160 | 175 | 6.8 | |

| GSR0280 | 28 | 36 | 3.2 | GSR1650 | 165 | 180 | 6.8 | |

| GSR0300 | 30 | 40 | 4.2 | GSR1700 | 170 | 185 | 6.8 | |

| GSR0320 | 32 | 42 | 4.2 | GSR1750 | 175 | 190 | 6.8 | |

| GSR0350 | 35 | 45 | 4.2 | GSR1800 | 180 | 195 | 8.1 | |

| GSR0400 | 40 | 50 | 4.2 | GSR1850 | 185 | 200 | 8.1 | |

| GSR0450 | 45 | 55 | 4.2 | GSR1900 | 190 | 205 | 8.1 | |

| GSR0500 | 50 | 60 | 4.2 | GSR1950 | 195 | 210 | 8.1 | |

| GSR0500H | 50 | 65 | 6.8 | GSR2000 | 200 | 215 | 8.1 | |

| GSR0530 | 53 | 63 | 4.2 | GSR2050 | 205 | 220 | 8.1 | |

| GSR0550 | 55 | 65 | 4.2 | GSR2100 | 210 | 225 | 8.1 | |

| GSR0550H | 55 | 70 | 6.8 | GSR2150 | 215 | 230 | 8.1 | |

| GSR0600 | 60 | 70 | 4.2 | GSR2200 | 220 | 235 | 8.1 | |

| GSR0600H | 60 | 75 | 6.8 | GSR2250 | 225 | 240 | 8.1 | |

| GSR0630 | 63 | 73 | 4.2 | GSR2300 | 230 | 245 | 8.1 | |

| GSR0650 | 65 | 75 | 4.2 | GSR2350 | 235 | 250 | 8.1 | |

| GSR0650H | 65 | 80 | 6.8 | GSR2400 | 240 | 255 | 8.1 | |

| GSR0670 | 67 | 77 | 4.2 | GSR2450 | 245 | 260 | 8.1 | |

| GSR0700 | 70 | 80 | 4.2 | GSR2500 | 250 | 265 | 8.1 | |

| GSR0700H | 70 | 85 | 6.8 | GSR2550 | 255 | 270 | 8.1 | |

| GSR0750 | 75 | 85 | 4.2 | GSR2600 | 260 | 275 | 8.1 | |

| GSR0750H | 75 | 90 | 6.8 | GSR2650 | 265 | 280 | 8.1 | |

| GSR0800 | 80 | 90 | 4.2 | GSR2700 | 270 | 285 | 8.1 | |

| GSR0800H | 80 | 95 | 6.8 | GSR2750 | 275 | 290 | 8.1 | |

| GSR0850 | 85 | 100 | 6.8 | GSR2800 | 280 | 295 | 8.1 | |

| GSR0900 | 90 | 105 | 6.8 | GSR2850 | 285 | 300 | 9.5 | |

| GSR0950 | 95 | 110 | 6.8 | GSR2900 | 290 | 310 | 9.5 | |

| GSR1000 | 100 | 115 | 6.8 | GSR2950 | 295 | 320 | 9.5 | |

| GSR1060 | 106 | 121 | 6.8 | GSR3000 | 300 | 325 | 9.5 | |

| GSR1100 | 110 | 125 | 6.8 | GSR3100 | 310 | 335 | 9.5 | |

| GSR1150 | 115 | 130 | 6.8 | GSR3200 | 320 | 345 | 9.5 | |

| GSR1200 | 120 | 135 | 6.8 | GSR3300 | 330 | 355 | 9.5 | |

| GSR1250H | 125 | 140 | 6.8 | GSR3400 | 340 | 365 | 9.5 | |

| GSR1250 | 125 | 140 | 6.8 | GSR3500 | 350 | 375 | 9.5 |

三、T Type Glyd Ring for Rod- GRT

1、Product structure characteristics

It consists of a PTFE seal and a rubber O-ring as a preload element.

It is a reciprocating seal that can withstand bidirectional effects of high pressure, low pressure and heavy load and alternating pressure.

2、Working conditions

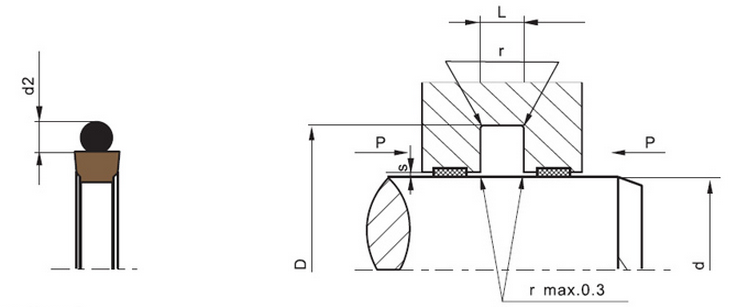

3、Assembly drawings and installation dimensions

| Shaft diameter dh9 | Groove diameter | Groove width | Fillet | Radial clearance Smax | O-ring section | ||||

| Standard Specification | Light | Heavy | DH9 | L+0.2 | r | 10Mpa | 20Mpa | 40Mpa | d2 |

| 3-7.9 | 8-18.9 | - | d+4.9 | 2.2 | 0.4 | 0.3 | 0.2 | 0.15 | 1.78 |

| 8-18.9 | 19-37.9 | - | d+7.3 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

| 19-37.9 | 38-199.9 | 8-18.9 | d+10.7 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

| 38-199.9 | 200-255.9 | 19-37.9 | d+15.1 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

| 200-255.9 | 256-649.9 | 38-199.9 | d+20.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

| 256-649.9 | 650-999.9 | 200-255.9 | d+24.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

| 650-999.9 | >=1000 | 256-649.9 | d+27.3 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

| >=1000 | - | 650-999.9 | d+38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

4、GRT Specification Table

| S/N | Shaft diameter | Groove diameter | Groove width | S/N | Shaft diameter | Groove diameter | Groove width | |

| dh9 | DH9 | L+0.2 | dh9 | DH9 | L+0.2 | |||

| GRT0040 | 4 | 8.9 | 2.2 | GRT0630L | 63 | 73.7 | 4.2 | |

| GRT0050 | 5 | 9.9 | 2.2 | GRT0630 | 63 | 78.1 | 6.3 | |

| GRT0060 | 6 | 10.9 | 2.2 | GRT0650 | 65 | 80.1 | 6.3 | |

| GRT0080 | 8 | 15.3 | 3.2 | GRT0700 | 70 | 85.1 | 6.3 | |

| GRT0100 | 10 | 17.3 | 3.2 | GRT0750 | 75 | 90.1 | 6.3 | |

| GRT0120L | 12 | 16.9 | 2.2 | GRT0800 | 80 | 95.1 | 6.3 | |

| GRT0120 | 12 | 19.3 | 3.2 | GRT0850 | 85 | 100.1 | 6.3 | |

| GRT0140L | 14 | 18.9 | 2.2 | GRT0900 | 90 | 105.1 | 6.3 | |

| GRT0140 | 14 | 21.3 | 3.2 | GRT0950 | 95 | 110.1 | 6.3 | |

| GRT0150 | 15 | 22.3 | 3.2 | GRT1000 | 100 | 115.1 | 6.3 | |

| GRT0160 | 16 | 23.3 | 3.2 | GRT1050 | 105 | 120.1 | 8.1 | |

| GRT0180 | 18 | 25.3 | 3.2 | GRT1100 | 110 | 125.1 | 6.3 | |

| GRT0190 | 19 | 29.7 | 4.2 | GRT1150 | 115 | 130.1 | 6.3 | |

| GRT0200L | 20 | 27.3 | 3.2 | GRT1200 | 120 | 135.1 | 6.3 | |

| GRT0200 | 20 | 30.7 | 4.2 | GRT1250 | 125 | 140.1 | 6.3 | |

| GRT0220L | 22 | 29.3 | 3.2 | GRT1300 | 130 | 145.1 | 6.3 | |

| GRT0220 | 22 | 32.7 | 4.2 | GRT1400 | 140 | 155.1 | 6.3 | |

| GRT0250L | 25 | 32.3 | 3.2 | GRT1450 | 145 | 160.1 | 8.1 | |

| GRT0250 | 25 | 35.7 | 4.2 | GRT1500 | 150 | 165.1 | 6.3 | |

| GRT0280 | 28 | 38.7 | 4.2 | GRT1600 | 160 | 175.1 | 6.3 | |

| GRT0300 | 30 | 40.7 | 4.2 | GRT1600H | 160 | 180.5 | 6.3 | |

| GRT0320 | 32 | 42.7 | 4.2 | GRT1650 | 165 | 180.1 | 8.1 | |

| GRT0350 | 35 | 45.7 | 4.2 | GRT1700 | 170 | 185.1 | 6.3 | |

| GRT0360 | 36 | 46.7 | 4.2 | GRT1800 | 180 | 195.1 | 6.3 | |

| GRT0380L | 38 | 48.7 | 4.2 | GRT1800H | 180 | 200.5 | 8.1 | |

| GRT0380 | 38 | 53.1 | 6.3 | GRT1900 | 190 | 205.1 | 6.3 | |

| GRT0400L | 40 | 50.7 | 4.2 | GRT2000 | 200 | 220.5 | 8.1 | |

| GRT0400 | 40 | 55.1 | 6.3 | GRT2100 | 210 | 230.5 | 8.1 | |

| GRT0420L | 42 | 52.7 | 4.2 | GRT2200 | 220 | 240.5 | 8.1 | |

| GRT0420 | 42 | 57.1 | 6.3 | GRT2300 | 230 | 250.5 | 8.1 | |

| GRT0450L | 45 | 55.7 | 4.2 | GRT2400 | 240 | 260.5 | 8.1 | |

| GRT0450 | 45 | 60.1 | 6.3 | GRT2500 | 250 | 270.5 | 8.1 | |

| GRT0500L | 50 | 60.7 | 4.2 | GRT2600 | 260 | 284.0 | 8.1 | |

| GRT0500 | 50 | 65.1 | 6.3 | GRT2700 | 270 | 294.0 | 8.1 | |

| GRT0550L | 55 | 65.7 | 4.2 | GRT2800 | 280 | 304.0 | 8.1 | |

| GRT0550 | 55 | 70.1 | 6.3 | GRT2900 | 290 | 314.0 | 8.1 | |

| GRT0560L | 56 | 66.7 | 4.2 | GRT3000 | 300 | 324.0 | 8.1 | |

| GRT0560 | 56 | 71.1 | 6.3 | GRT3100 | 310 | 334.0 | 8.1 | |

| GRT0600L | 60 | 70.7 | 4.2 | GRT3200 | 320 | 344.0 | 8.1 | |

| GRT0600 | 60 | 75.1 | 6.3 | GRT3400 | 340 | 364.0 | 8.1 |

四、Glyd Ring for Rod - SPNO

1、Product structure characteristics

It consists of a PTFE seal and a rubber O-ring as a preload element.

It is a reciprocating seal that can withstand bidirectional effects of high pressure, low pressure and heavy load and alternating pressure.

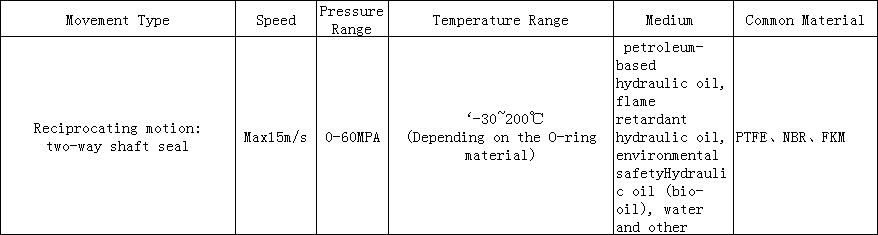

2、Working conditions

3、Assembly drawings

4、SPNO Specification Table

| S/N | d | D | H | L+0.2 | S/N | d | D | H | L+0.2 | |

| SPNO 0120 | 12 | 18 | 3.0 | 3.2 | SPNO 0500 | 50 | 65 | 6.3 | 6.5 | |

| SPNO 0140 | 14 | 20 | 3.0 | 3.2 | SPNO 0560 | 56 | 71 | 6.3 | 6.5 | |

| SPNO 0160 | 16 | 22 | 3.0 | 3.2 | SPNO 0600 | 60 | 75 | 6.3 | 6.5 | |

| SPNO 0180 | 18 | 24 | 3.0 | 3.2 | SPNO 0630 | 63 | 78 | 6.3 | 6.5 | |

| SPNO 0200 | 20 | 26 | 3.0 | 3.2 | SPNO 0700 | 70 | 85 | 6.3 | 6.5 | |

| SPNO 0220 | 22 | 31 | 3.8 | 4.0 | SPNO 0750 | 75 | 90 | 6.3 | 6.5 | |

| SPNO 0250 | 25 | 34 | 3.8 | 4.0 | SPNO 0800 | 80 | 95 | 6.3 | 6.5 | |

| SPNO 0280 | 28 | 37 | 3.8 | 4.0 | SPNO 0850 | 85 | 100 | 6.3 | 6.5 | |

| SPNO 0300 | 30 | 39 | 3.8 | 4.0 | SPNO 0900 | 90 | 105 | 6.3 | 6.5 | |

| SPNO 0320 | 32 | 41 | 3.8 | 4.0 | SPNO 0950 | 95 | 110 | 6.3 | 6.5 | |

| SPNO 0360 | 36 | 45 | 3.8 | 4.0 | SPNO 1000 | 100 | 115 | 6.3 | 6.5 | |

| SPNO 0400 | 40 | 49 | 3.8 | 4.0 | SPNO 1050 | 105 | 120 | 6.3 | 6.5 | |

| SPNO 0450 | 45 | 54 | 3.8 | 4.0 | SPNO 1100 | 110 | 125 | 6.3 | 6.5 | |

| S/N | d | D | H | L+0.2 | S/N | d | D | H | L+0.2 | |

| SPNO 1150 | 115 | 130 | 6.3 | 6.5 | SPNO 2300 | 230 | 250 | 9.8 | 10.0 | |

| SPNO 1200 | 120 | 135 | 6.3 | 6.5 | SPNO 2400 | 240 | 260 | 9.8 | 10.0 | |

| SPNO 1250 | 125 | 140 | 6.3 | 6.5 | SPNO 2500 | 250 | 270 | 9.8 | 10.0 | |

| SPNO 1300 | 130 | 145 | 6.3 | 6.5 | SPNO 2600 | 260 | 280 | 9.8 | 10.0 | |

| SPNO 1350 | 135 | 150 | 6.3 | 6.5 | SPNO 2700 | 270 | 290 | 9.8 | 10.0 | |

| SPNO 1400 | 140 | 155 | 6.3 | 6.5 | SPNO 2800 | 280 | 300 | 9.8 | 10.0 | |

| SPNO 1450 | 145 | 160 | 6.3 | 6.5 | SPNO 2900 | 290 | 310 | 9.8 | 10.0 | |

| SPNO 1500 | 150 | 170 | 9.8 | 10.0 | SPNO 3000 | 300 | 320 | 9.8 | 10.0 | |

| SPNO 1600 | 160 | 180 | 9.8 | 10.0 | SPNO 3100 | 310 | 330 | 9.8 | 10.0 | |

| SPNO 1700 | 170 | 190 | 9.8 | 10.0 | SPNO 3200 | 320 | 340 | 9.8 | 10.0 | |

| SPNO 1800 | 180 | 200 | 9.8 | 10.0 | SPNO 3300 | 330 | 350 | 9.8 | 10.0 | |

| SPNO 1900 | 190 | 210 | 9.8 | 10.0 | SPNO 3400 | 340 | 360 | 9.8 | 10.0 | |

| SPNO 2000 | 200 | 220 | 9.8 | 10.0 | SPNO 3500 | 350 | 370 | 9.8 | 10.0 | |

| SPNO 2100 | 210 | 230 | 9.8 | 10.0 | SPNO 3600 | 360 | 380 | 9.8 | 10.0 | |

| SPNO 2200 | 220 | 240 | 9.8 | 10.0 | SPNO 3700 | 370 | 390 | 9.8 | 10.0 | |

| SPNO 2240 | 224 | 244 | 9.8 | 10.0 | SPNO 3800 | 380 | 400 | 9.8 | 10.0 |